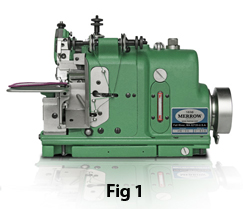

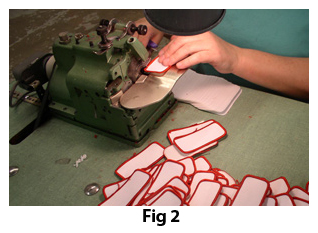

In 1956 the Eagle badge was produced with a merrowed or rolled edge. This was the first uniform insignia to have a rolled edge. The Merrow machine, fig.1,

produces a uniform rolled edge. Different machine models were capable of producing different borders; the standard rolled edge, the narrow or wide rolled edge and the flat rolled edge. Merrowing the border is a process that occurs after the emblem is embroidered and cut to shape. The worker using a Merrow machine applies a rolled edge to each emblem one at a time. See fig 2.

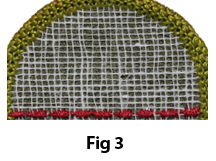

During the late 1950s the patch suppliers approached the BSA with a proposal to improve the “look” of merit badges. They suggested switching from the crimped style merit badge to a merrowed or rolled edge. They offered several reasons for the change. The rolled edge made the badges look more uniform on the sash and it made merit badges easier to sew onto sashes. There were advantages for council shops and the suppliers as well. The crimped Khaki merit badge was difficult to handle in the factory and council shops. The sizing applied to the back helped to make the badges stiff but since it was hand applied with a brush it was often not uniform. The crimped under part of the badge frequently unfolded partly or fully during handling in the factory and the council shop. Handling caused some badges to appear used. Merit badges were not the only badges to experience these issues. Rank and position badges had similar issues. Suppliers found that adding a gauze backing, fig 3,

to badges gave them enough body to withstand the rigors of handling. Adding gauze to the back of emblems worked well for rank and position badges and they, were produced with the gauze backing for several years in the early 1950s. Unfortunately over time the gauze backing loosened along the edge of the badges causing the badge to a have a ragged edge look. In addition, folding the gauze reinforced badges to create a uniform shape that proved challenging for scouts and parents. Suppliers tried to pre-fold the edges of the badges to create a uniform look on the shirt or sash. The pre-fold created handling issues so it was abandoned and rank insignia was changed in 1955 to include an embroidered border with a cut edge. Suppliers tried applying gauze to the back of crimped merit badges but they found it was not possible to crimp the edge. Suppliers suggested the same cut edge border as rank but the concept was quickly dismissed. Suppliers then presented sample merit badges with a Merrowed edge. This new look was quickly accepted.

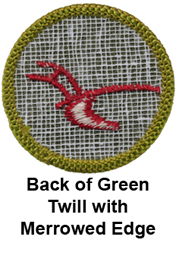

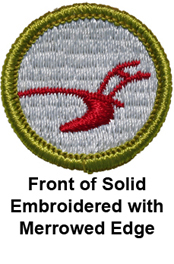

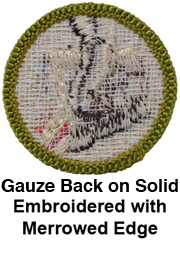

Starting in 1961 all merit badge titles were produced with the new rolled edge. The embroidered design for each new rolled edge was the same as the khaki crimp embroidered design. Therefore, some titles had the same twill background as their predecessor in khaki crimp, i.e. Agriculture, and some had a solid embroidered design and background, i.e. Landscaping. All rolled edge twill background badges have a gauze backing that stiffens the badge and reduced handling problems in the factory. Suppliers applied the gauze reinforcing to the solid embroidered badges also but quickly discovered solid embroidered badges did not need the gauze reinforcing. Simply applying a light starch stiffened the badges sufficiently to avoid handling problems. Several examples of solid embroidered rolled edge badges exist in collections with gauze reinforcing. In 1969 all the twill background badges were redesigned to include a solid embroidered background. The Merrowed or rolled edge series was produced between 1961 and 1971.

The 1961 - 71 Merrowed edge series has 120 titles. Several titles have multiple major design variations, thus the set of all titles and variations is 206 merit badges. There are several ways to collect this series. One method is to collect one merit badge representing each title, 120 badges. Another method is to collect all major variations of each title, 206 badges. In years past many collectors have chosen to collect the rolled edge twill with gauze backing as a group, 74 titles or 80 variations, known as type “F” in many guide books, and the solid embroidered cloth back as a group, 115 titles or 126 variations, known as type “G” in many guide books. Another method is collect the 1961 – 1968 badges as a group, 119 titles or 128 variations, both twill and solid, and the 1969 – 1971 as a group, solid cloth backs 115 titles or 118 variations. The choice of how to collect the Merrowed Edge group is up to each collector. Have fun building your collection.

1961 - 71 Rolled Edge Front and Back Examples

Silver Border Merrowed Edge Badges

In the late 1960’s the National Committee for Uniform and Badging sought a way to make Eagle Required badges stand out on uniforms and sashes. They introduced and approved a border change to Eagle required merit badges. They selected a silver color border to match the silver Eagle pendant and scroll. In late 1967 BSA National Supply asked Lion Brothers to supply samples of a merit badge with a silver color border. Lion, while filling a routine order for green border Bee Keeping, increased the quantity and bordered 1000 with a silver color. Bee Keeping was chosen by chance and happened to be a title Lion was making when National supply asked for the samples.

The National Committee for Uniforms and Badging in an effort to introduce the new design concept sent letters explaining the proposed change along with 2 samples of the silver bordered Bee Keeping to each Council Executive. The samples were never meant to be released. They were prototypes only. In 1968 Lion was given the order to border all Eagle required merit badges with the new silver color. The new silver border merit badges were officialty released in 1969.

Manufacturing Related Design Variations

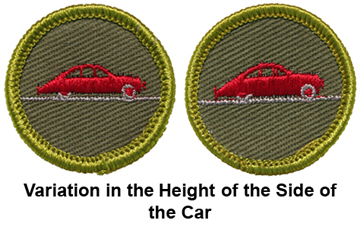

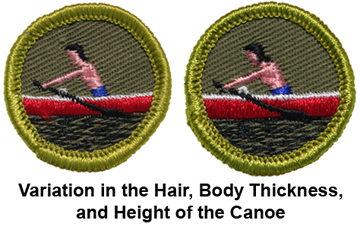

During the manufacturing process minor design variations occur. There are multiple sources of this variation. The machines used during the 1960s were NOT computer controlled. They used paper tapes that would wear out and need to be reproduced. Large embroidery suppliers have multiple machines that were not identical thus they used different tapes for different machine models. The other main source of manufacture variation is multiple suppliers making the same badge. When more than one supplier is used the normal process for BSA Supply is to send samples of a merit badge being produced by a supplier to the new or alternate supplier. The new supplier tries to replicate the design as close as possible, but there is almost always variation in the design from one supplier to another. The matched pairs below are samples showing the design variations between machines and between suppliers. The compilers, have identified dozens of these manufacturing minor variations. We chose to include only a few to illustrate the design variations related to manufacturing process variations.

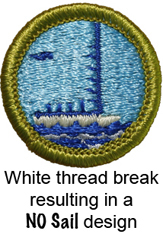

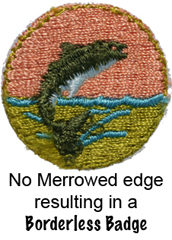

Embroidery ERRORS and DEFECTS

Manufactures of merit badges have quality standards and perform inspections. Occasionally badges with defects are missed by inspectors, and are shipped to National Supply. These defective badges are then sold by a Scout Shop. The authors of this article do not consider these defective badges as official variations and are not listed in the main list. Below are several samples of different types of defects that can happen and then get listed in some collector books.

In 1971 merit badge suppliers in an effort to reduce the number of merit badges discarded during the production process began experimenting with adding plastic to the back of the badges. The addition of plastic to the back proved very beneficial to the suppliers and scouts. Beginning in late 1971 all merit badges were produced with the new plastic backing. The application of the plastic back between 1971 and 1976 was a very manual process. Occasionally during the plastic backing application process a sheet of merit badges were missed and allowed to be bordered without the plastic backing. Also on occasion the plastic sheet was not aligned well and a couple of the badges on the sheet did not get the plastic backing and were bordered and shipped. BSA National Supply did not consider the lack of plastic on a few badges as an unacceptable defect. Thus from time to time a few badges that did NOT have plastic backing were included in the shipment with plastic backed badges. For the vast majority of titles the lack of plastic backing got unnoticed. These defect badges only become an issue when a badge title or design that was introduced after 1972 is produced without the plastic backing.

These post 1972 titles and designs with cloth backs pose an interesting problem for collectors. Many collectors consider these defects as cloth back badges and include them in the 1969 - 71 “G” series. The compilers of this guide do NOT include them as part of the cloth back series because they were NOT available for scout to earn during the 1969 - 71 period. They are included in the plastic backed series as defects. Also, many of these badges show evidence of partial plasticizing

Below are photos of several known examples of this defect.