Fabric Color:

Fabric color has been debated for years. Is it Khaki, Tan Green, Olive or some other shade. The reality is it is all of the fore mentioned. Today color is measured with Spectrophotometers, Colorimeters and Pantone charts. In the teens, 20s, 30s and 40s color in the mill was monitored to a very different standard. The image below is a reproduction of a sample color card used in the mill that produced BSA fabric. Using a card like this one allowed the cloth manufacturer to ship many shades of fabric. The one thing to always keep in mind with manufacturing is the tighter the tolerance specification the more expensive the product. This reproduction was made from a chart shown to the author by the grandson of the mill Forman who actually made fabric for the BSA.

Heavyweight Cloth:

The official uniform cloth was defined as “2 point 10 khaki”. The is a dense weave broadcloth. This was the official cloth use for merit badges until 1933. In 1933 the BSA experimented with less dense broadcloth to reduce cost. This less dense cloth was only used in 1933 and 34. The standard 2 point 10 khaki being dense does NOT allow light to be seen through it when held you attempt to look through it at a 60 watt light bulb from 5 feet.

Lightweight Cloth:

In 1938 the Uniform Committee agreed to change the cloth standard from the “2 point 10 khaki” to “5 oz/yd2 khaki”. This is a lightweight broadcloth fabric. When you attempt to look through it at a 60 watt light bulb from 5 feet you can see lots of light between the threads.

Fine Twill:

In 1943 the BSA experienced a shortage of cloth due to World War II. The supply division had to find substitutes. One of the two substitutes used during the war was a fine smooth lightweight weave fabric. This fabric was used in 1943 and 1944.

Khaki:

In 1947 the BSA was once again able to define a cloth standard and not be subject to war shortages. The cloth standard returned to the 5 oz/yd2 before the war. The standard called for a darker green than the pre-war standard. When washed the dark green Khaki color fads to a paler green thus making it difficult to distinguish washed khaki cloth from per-war lightweight cloth.

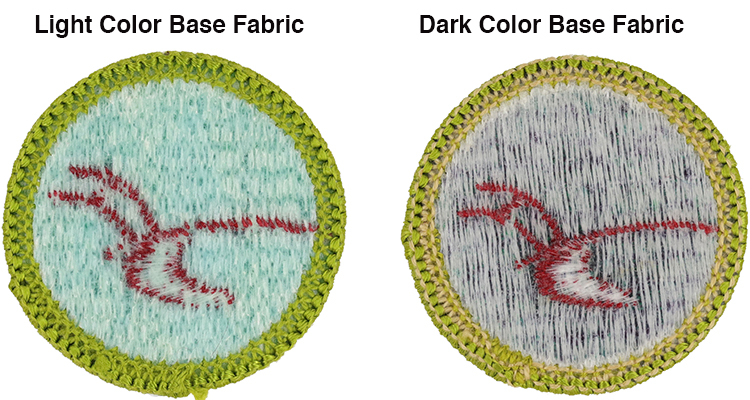

Base Material used for Fully Embroidered Badges:

The color base material is immaterial to the manufacturer. They can use any color they can purchase inexpensively. What does matter is the weight and weave, as these to attributes affect the embroidery process. During any embroidery run it is very possible the manufacturer will use several base fabric colors. Sometimes the base material can affect the color of the back of the badge. The images below show the same badge with a clear waffle back. One is on a light base material and the other on a dark base material. The badge fronts show NO difference.