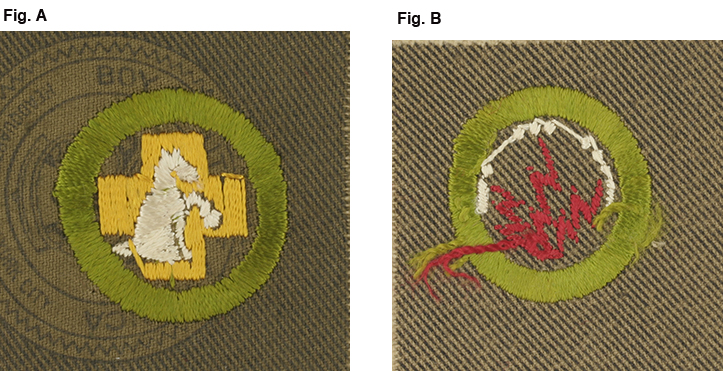

Plain Printed Back:

From 1912 until approximately 1935 all badges had a brown or black imprint on the back. The back of the badge has NO additional material such as starch, gauze, whit glue or plastic. Figure A shows a plain printed back with a partial printed seal and lines. Figure B shows a plain printed back with only printed lines.

Starched Printed Back:

Approximately 1935 manufacturers began to add cornstarch to the back of the badge. This was done for two reasons. First it prevented the edge of the badge from unraveling during handing, and second it helped the badge maintain the crimped edge in handling, shipment and inventory at BSA. The image below shows the back of a badge with a black imprint under the starch.

Starched Plain Back:

In approximately 1937 the seal and lines imprint was removed from badge backs. Cornstarch was added to the back of the badge. This was done for two reasons. First it prevented the edge of the badge from unraveling during handing, and second it helped the badge maintain the crimped edge in handling, shipment and inventory at BSA. The image below shows the back of a plain starched badge.

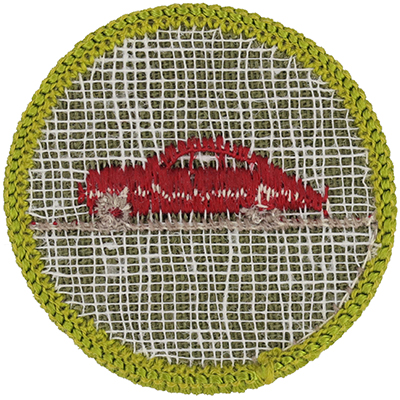

Gauze Reinforced Starch:

In 1960 manufacturers began adding a gauze material to the back of the badge. In addition to the gauze a starch coating was applied to affix the gauze to the broadcloth. The addition of the gauze was done to improve the merrowing process. The image below shows a gauze reinforced back.

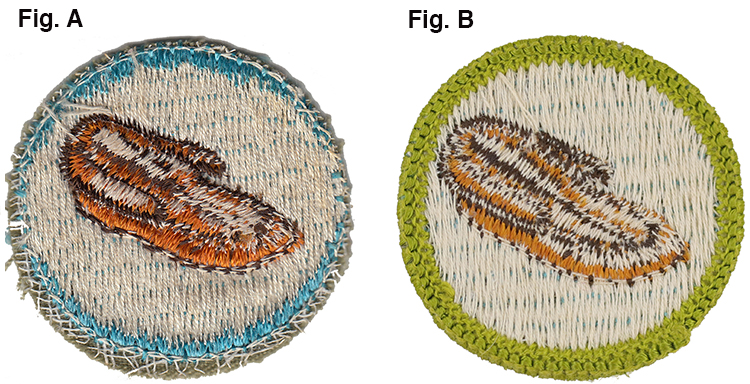

Starched Cloth Back:

In 1961 the first full embroidered merit badges with a merrowed edge were produced. The full reverse of the badge is embroidered and coated in a light starch. These badges were embroidered several at a time on a square of cloth. The badges were then cut out and the merrowed edge added to finish the badge. The starch coating was to keep the edge of the embroidery from unraveling during transit from the embroidery station to the merrowing station. Figure A shows the back of a fully embroidered badge prior to the merrow edge being added. Figure B shows a starched cloth back badge with merrow edging.

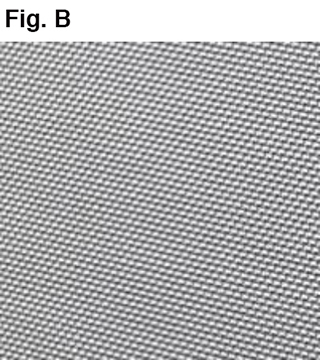

Blue Waffle Plastic Back:

In 1972 embroiders changed their process and introduced plastic backing onto badges. The plastic was added to the back to counteract the losses embroiders were incurring due to transport, storage, and handling between the embroidery process and the merrowing process as well as handling during the merrowing process. The introduction of the plastic reinforced back lowered loss and increased speed. To make the plastic easy for the worker to see, embroiders started with plastic with a bluish tint. The application of the plastic is what gives it a distinct waffle pattern. From 1972 until 1975 merit badge were embroidered 25 badges per cloth square. Then the cloth square was place upside down in a heat press, figure A. The a square of blue polyethylene plastic was placed over the back of the badges. Next a sheet of silicon reinforced cloth was place on top of the plastic. Then the heat press was closed and the badge and plastic heated to 350 degrees for 60 seconds. The pattern in the reinforced silicon coated cloth is what caused the waffle pattern. Figure B shows a close up of the Silicon reinforced cloth. After the plastic was applied the badges were cut out and sent to the merrowing machine for bordering. The badge image shows a close up of a blue waffle plastic back. The white dots are tiny wells like in a waffle.

Clear Waffle Plastic Back:

After workers became comfortable to working with the new blue plastic material embroiders found the clear polyethylene plastic was less expensive and they switched from blue tint to clear. The waffle pattern in the clear is the result of the same process being used for blue and clear. The image below shows a close up of a clear waffle plastic back. The white dots are tiny wells like in a waffle.

Clear Molded Plastic Back:

In 1976 embroiders introduced a change in the process to reduce the amount of work steps the embroidery machine worker did. Using the heat press cause the worked to have to play close attention to the alarm after 60 seconds and unclamp the machine and remove the badges and perform the process over again. The change was the introduction of a mini oven with a conveyor, figure A. The worker simply turned the square of badges upside down placed a sheet of plastic over the back put the on the conveyor and waited for the to drop onto a table. This meant the worked did not have to monitor the machine like when using a heat press. This new conveyor oven process gave the back a new look. The plastic melts and conforms to the embroidery giving it a molded look and feel. THe badge image shows a close up of a molded back merit badge.

Scout Stuff Imprint, 2010 100th Anniversary Imprint, & Since 1910 Imprint:

In 2002 the BSA determined it need to add an imprint to the back of all badges to protect Scouting from counterfeit badges and the badges being used for programs other the Scouting. From 2002 to 2010 the imprint was the “Scout Stuff” imprint. For the 100th Anniversary of Scouting the imprint was changed to the “2010