Continuous Loop Embroidery:

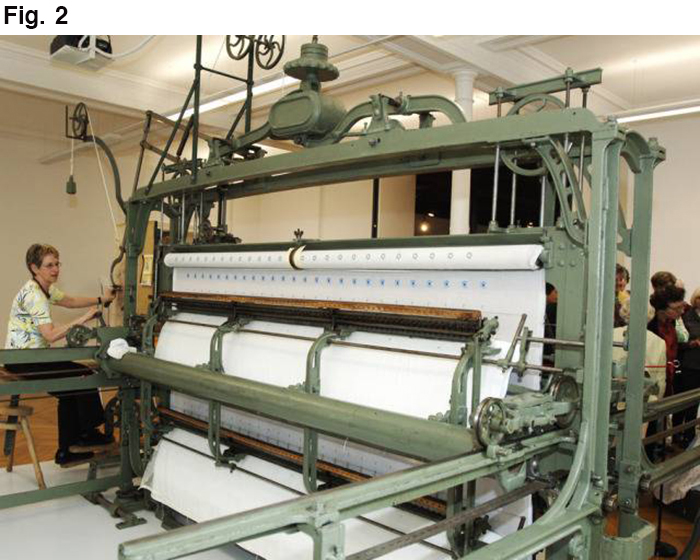

In 1873, Alphonse Kursheedt imported twelve of the then new embroidery hand looms from St. Gallen, making him the first American to use a mechanized embroidery process. The looms used multiple needles and were an unbelievable improvement over the age-old process of stitching by hand. They were, however, powered manually.

This type of embroidery was used for merit badges until 1939. The official name of the machine used is “Handmachine”. Fig 1 and 2 show the front and figure 3 the back of the machine. Figure 4 shows the operator working the machine and figure 5 shows a close-up of the design being embroidered.

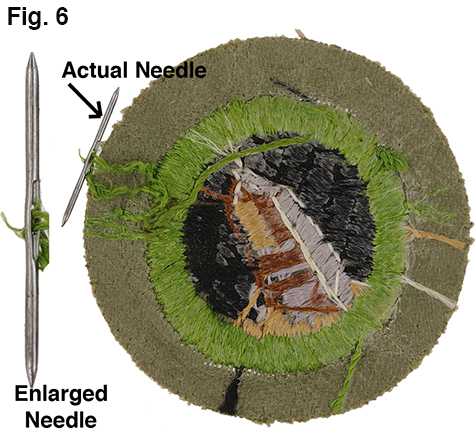

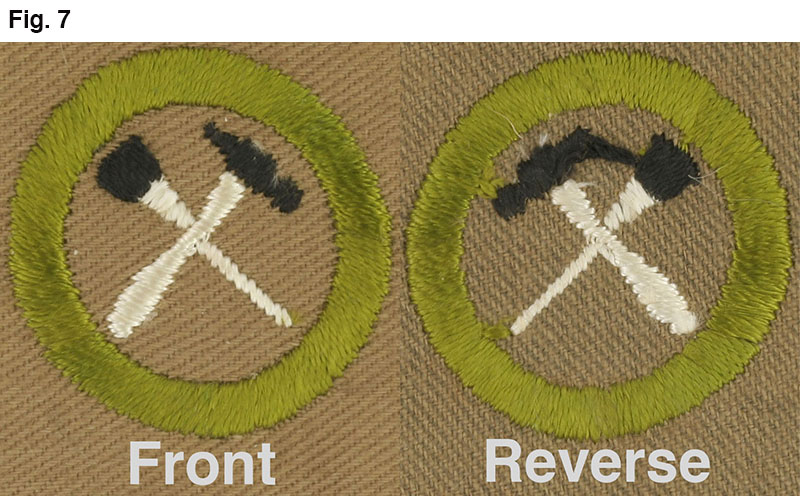

Instead of taking the needle to the fabric, fabric moved to meet the needle, which had a point at each end and an eye in the middle, figure 6. The merit badge in figure 5 was discovered with the needle still attached to the thread. The length of each embroidery thread used by this machine is 24 inches. The fabric moved back and forth until the 24 inches was used and then the needles rethreaded. The process creates a similar look on the front and back. Figure 7 shows the front and back of a continuous loop embroidered merit badge. The process allowed stitching in any direction. Designs were six times the size of the original and a great amount of coordination was needed to stitch. The operator used his left hand to guide a scribe around the pattern diagram. His right hand cranked a wheel that pushed needles through the fabric and his feet operated the clamps that gripped the needles.

Lock Stitch Embroidery:

This is also known as “Schiffli” embroidery. Merit badges started being made using Schiffi style embroidery machines in 1939. Issac Groebli of Switzerland invented the first practical Schiffli Embroidery machine. This machine was based on the principals introduced by the newly invented sewing machine. Groebli’s machine utilized the combination of a continuously threaded needle and shuttle containing a bobbin of thread. The shuttle itself looked similar to the hull of a sailboat. His machine came to be known as a schiffli machine. "Schiffli" in the Swiss dialect of the German language , means "little boat".

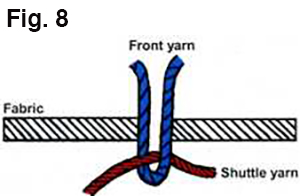

The Schiffli machine is a variation on the sewing machine. It embroiders with a front thread and bobbin thread (yarn at the back of the cloth) which from together a lock stitch, similar to that of a sewing machine. Figure 8 illustrates the two different threads used to make a stitch.

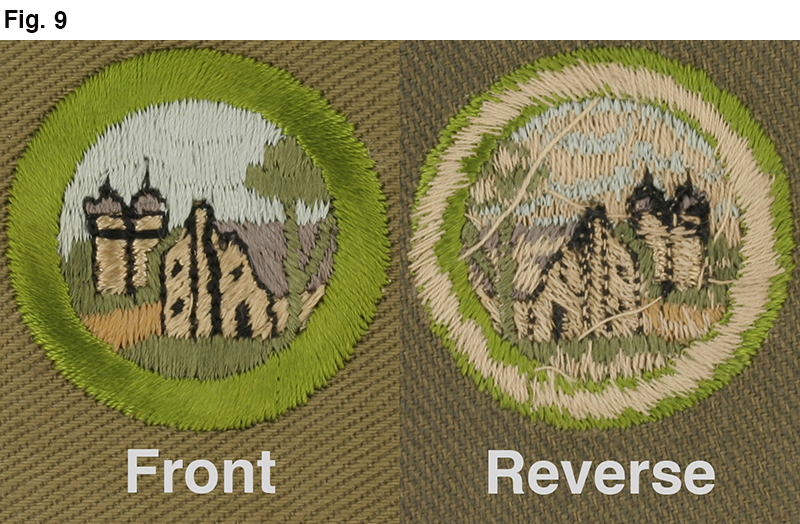

The front yarn is threated in a needle which passes through the goods to a predetermined point. It is then retracted slightly, and the friction of the goods holds the thread, forcing a loop to be formed. A shuttle containing the yarn which is attached to the previous stitch in the back of the goods is driven through this loop, and the needle is driven again slightly further into the fabric, to allow enough thread for the shuttle to pass through the loop. Figure 9 shows the front and back of a lock stitch embroidered merit badge. Note the white bobbin stitch on the reverse. The badge in figure 9 was made in the late 1920s. An embroider supplied this as a sample of the Schiffli process using cotton thread. West rejected the idea because of the look of the cotton compared to the silk. The conflict in Asia in 1939 changed everything.

There are several advantages to using a lock stitch: significantly longer threads can be used. The threads are less prone to breakage, and the stitch rate is much faster. This means fewer interruptions due to broken thread and less frequent stops to re-thread. Unlike the hand embroidery machine, the needles do not pass and the thread is not drawn completely through the fabric. Since the manual embroidery machine required the thread to be pulled completely through the fabric, after each front and back side stitch, its thread length was limited by the depth of the machine. A schiffli spool could hold more than 500 yards of embroidery thread. The schiffli machine is only limited by the length of thread that can fit on the bobbin.

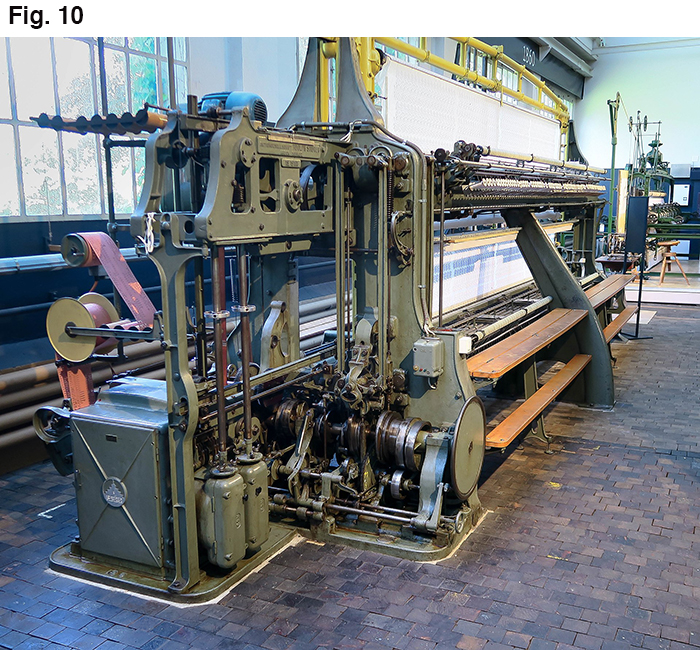

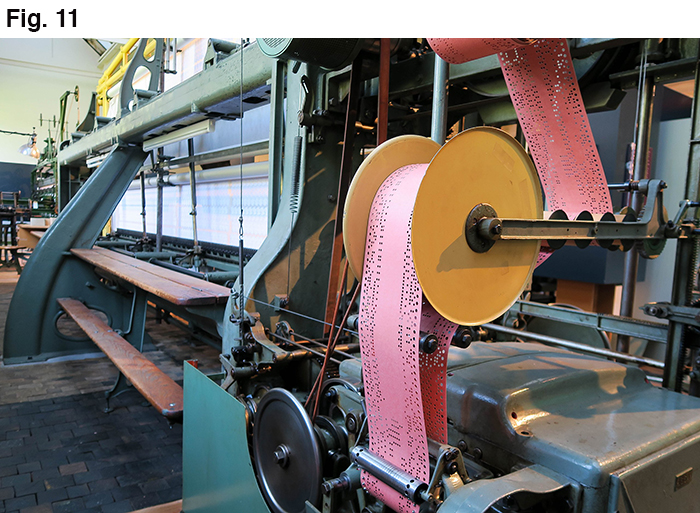

Figures 10 & 11 show a Schiffli type machine with the automat paper tape. This is the type of machine scout badges would have been made on until the 1990s.

Photo by Chris Riedener

Photo by Chris Riedener

Several examples of the early embroidery machines have been preserved in various museums. Functioning embroidery machines can be seen at the Schaustickerei in Plauen, Germany, Industriekultur museum in Neuthal, Switzerland, and the Textile Museum in St. Gallen. The Saurer museum in Arbon, Switzerland has both manual and the later Schiffli machines as well as the associated needle threading, bobbin winding, card punching and card duplicating machines. The Schiffli machine is still in use. It has evolved, but its basic form is still recognizable today. Paper punch cards have been replaced by a computer.