In the early 1930s the committee for badges  and uniforms became concerned with the presentation or look of merit badges on sashes. The lack of uniformity of the folded under square merit badges created an inconsistent and/or unprofessional look to sashes and uniforms as. Figure 1.

and uniforms became concerned with the presentation or look of merit badges on sashes. The lack of uniformity of the folded under square merit badges created an inconsistent and/or unprofessional look to sashes and uniforms as. Figure 1.

The solution the badge committee and the embroiderers agreed upon was to die-cut the merit badge to a uniform 2 inches round and machine fold/crimp the edge creating a uniform 1 ¾ inch round badge. These new standardized round badges when placed in neat rows on a sash created a very professional look. See Fig 2.

Thus in 1933 the official standard for merit badges changed to a 2 inch round badge made of official uniform cloth with trademarked black imprinted seals and lines on the back and merit badges are embroidered with silk thread so that the base cloth twill angles to the right to match the twill angle on sashes.

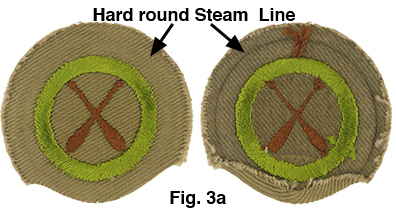

The embroider used a crimping machine that steamed the badge during the crimping process. The steaming process created a hard round fold. When a true wide crimp is unfolded the perfect round circle crimp line is visible. See Fig. 3a. Many scouts attempted to fold down square merit badges and sew them on a sash to look like wide tans. There are two giviways to these being folded down squares. First they are usually not perfect round circles and second they do not have the hard steam fold lines. See the two samples of folded squares to look like wides in Fig. 3b

The Great Depression Affects Scout Badges

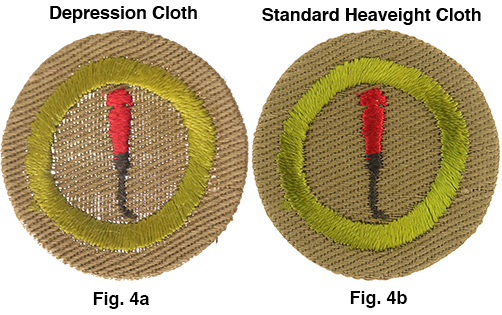

In the early thirty’s the US was in the middle of the Great Depression. US citizens had very little money to spend on non-essentials. The BSA, like most organizations and businesses were seeking ways to control prices. The BSA approached the cloth manufacturer, and asked for ideas. Together they agreed on a new cloth made using a smaller diameter thread. The changes lowered the cost of the cloth and resulted in price containment. The new cloth, dubbed, “Depression Cloth” is easily identified. Depression Cloth is a loose weave whereas the normal standard heavyweight uniform cloth of the period is tightly woven and dense. The easy method to distinguish “Standard” from “Depression” cloth is to perform the light test. Hold the badge in a way that there is a light source behind the badge, 75 watt at 3 feet is sufficient. Depression cloth will allow light to pass between the threads and look like Figure 4a. Standard cloth will not let light pass between the threads and will look like Figure 4b.

Depression cloth was only used during 1933 and 1934. The cloth did not hold up to normal wear or the washing methods of the 1930s. Depression cloth was abandoned in 1934 and all badges and uniforms returned to the heavyweight broadcloth used during the 1920s.

Reworked Square Badges

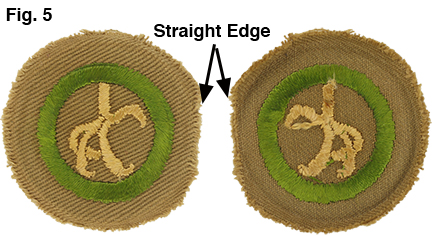

When the first wide tan merit badges arrived at national supply there were still some square merit badges in national supply’s inventory. Rather than discarding the squares the squares were returned to the embroider. The returned squares were die-cut to round, crimped and returned to national supply. For the most part the reworked squares are indistinguishable from wide tans made in 1933 and 1934; however not all squares could be converted to wide tans. The embroidery on some squares was off centered and close to the edge. In some cases the off centered design allowed the badge to be die-cut, but there was not enough material on one side to create a full crimp. Unfolded these badges are 2 inch round with a short straight edge on one side. See Fig 5

Manufacturing Related Broadcloth Color Variations

The committee for uniforms and badges created a color standard for uniform broadcloth. The standard included the ideal color plus an acceptable range of variation. During the 1920’s and 30’s the acceptable range of color for uniform cloth ranged from a tan color to a khaki green. Fig. 6 shows the color card for fabric manufactures. The collector who collects wide tans should keep in mind every dye lot of broadcloth made was different in color. The authors and editors of this information do not use broadcloth color as a variable to determine subgroups.

Fig. 6

Manufacturing Related Design Variations

During the manufacturing process minor design variations occur. There are multiple sources of this variation. The machines used during the 1930s were NOT computer controlled. They used paper tapes that would wear out and need to be reproduced. In addition, the embroidery suppliers had multiple machines that were not identical thus they used different tapes for different machine models. The other main source of manufacture variation is multiple suppliers making the same badge. When more than one supplier is used the normal process for BSA Supply is to send samples of a merit badge being produced by a supplier to the new or alternate supplier. The new supplier tries to replicate the design as close as possible, but there is almost always variation in the design from one supplier to another. These unintended small variations due to the manufacturing process present a real challenge to collecting. At what point is the variation between badges different enough to classify both as separate varieties? This question will be debated for many years to come. The matched pairs below are samples showing the design variations between machines and between suppliers. Collectors have identified dozens of these manufacturing minor variations. On the website we classify the minor variations as MVE.

Manufacturing Related Embroidery Color Variations

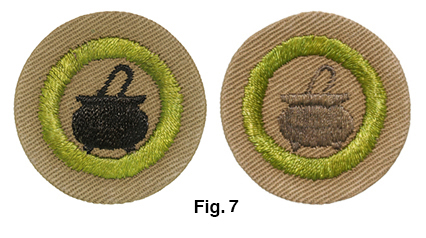

Another source of variation from badge to badge is the embroidery thread color. Let’s begin with black. Look at the two cooking badges in Fig 7.  One has a black pot and the other brown. The official design and work order at the embroider calls for black not brown. So why is the brown pot instead of black? There are two possible answers; they ran out of black and substituted brown. The second and more likely answer is they used black over-dyed thread and the black dye faded and the under dye is now showing. It is common practice in thread making to over-dye. Over dying is a practice to reduce waste. If a thread maker dyes a batch of white thread yellow and the color is not correct the thread is NOT thrown away but can be over dyed to a darker color like medium green. If the medium green is not correct then the thread can be dyed a darker color again. The last stop for all color errors is over dye with black. The dyes used in the 1930’s are not as color fast as modern dyes thus a variety of environmental conditions can cause the top color to fade and the under color to show.

One has a black pot and the other brown. The official design and work order at the embroider calls for black not brown. So why is the brown pot instead of black? There are two possible answers; they ran out of black and substituted brown. The second and more likely answer is they used black over-dyed thread and the black dye faded and the under dye is now showing. It is common practice in thread making to over-dye. Over dying is a practice to reduce waste. If a thread maker dyes a batch of white thread yellow and the color is not correct the thread is NOT thrown away but can be over dyed to a darker color like medium green. If the medium green is not correct then the thread can be dyed a darker color again. The last stop for all color errors is over dye with black. The dyes used in the 1930’s are not as color fast as modern dyes thus a variety of environmental conditions can cause the top color to fade and the under color to show.

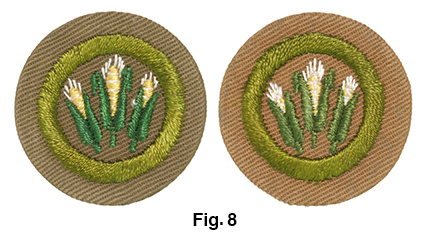

For all colors in a design there were color standards and acceptable color ranges. When the design, for example specified medium green the acceptable thread color could vary from a light medium green to a dark medium green. See Fig 8. This color variation could occur within the batch of badges or batch to batch.

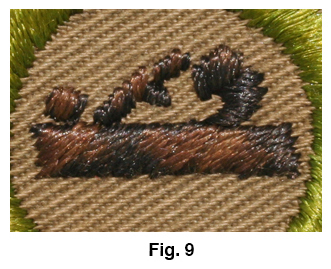

Over dyed threads presents the greatest challenge to classifying different varieties. As time passes and the environment effects the top dye color we see a wide range of colors appearing for the same design. One way to know the design color is the result of under dye showing is the thread appears variegated, Fig. 9. The website makes no attempt to show all the possible color/shade variations do the over dye effect.

Embroidery ERRORS and DEFECTS

Embroiderers of merit badges have quality standards and perform inspections. Occasionally badges with defects are missed by inspectors, and are shipped to National Supply. These defective badges are then issued. The authors and editors of this article classify these as errors. There are five errors:

Classifications

Badge titles are 6 alpha characters. Wide Tans are “Type B” merit badges. Within the type B group are three sub-groups: B1 is Depression broadcloth, B2 is Heavyweight broadcloth, B3 is Heavyweight with starched backing. Significant design variations are designated with a small letter such a B1a, or B1b. To date several significant design variations have been identified. Cloth color and minor thread color variations are classified with the letters MVE (Minor Variation Exist). Multiple variations would be classified as MVE1, MVE2, etc. Errors 1 – 4 have the identifier “error”.

Here are several samples of the classification system:

The 1934 - 35 Wide Tan series has 110 titles. To date we have identified 38 titles produced in “Depression Cloth” and 102 titles produced in “Heavy Weight Uniform Cloth”. Also, a couple of titles have significant design variations. There are several ways to collect this series. One method is to collect one merit badge representing each title, 102 badges. Another method is to collect all known titles on each cloth type, 137 badges. Collecting all design and manufacturing variations is another way to collect this series. The choice of how to collect the Wide Tan series is up to each collector. Have fun building your collection.